Special conductivity Mohala o moholo oa phetisetso ea mats'oao Alloy enamelled round terata Thepa e phahameng ea mochini e ka etsoa

Mohala oa motsoako ke eng

1.1 E le ho ntlafatsa ts'ebetso e khethehileng ea terata ea enamelled, terata ea alloy ke terata ea enamelled eo mokhanni oa eona a entsoeng ka alloy ea koporo. Alloy terata e na le conductivity e khethehileng ea motlakase, thepa ea mochini, ho hanyetsa mokhathala le ho hanyetsa ho hoholo ho hoholo. Ho finyella litlhoko tse khethehileng tsa tšebeliso ea bareki, k'hamphani ea rona e fana ka mefuta e fapaneng ea lithapo tse nang le alloy enamelled. E le ho matlafatsa litšobotsi tse ling tsa terata, re tla tsoela pele ho sebetsana le lithapo tsa alloy ho finyella litlhoko tsa tšebeliso ea bareki.

1.2. Re ka fana ka koporo silevera alloy, koporo tin alloy, koporo nickel alloy, silevera plating, nickel plating le tse ling tse alloy lithapo enamelled, hammoho le alloy conductors ho ea ka ditshebediso tse fapaneng.

Mofuta oa alloy enamelled terata

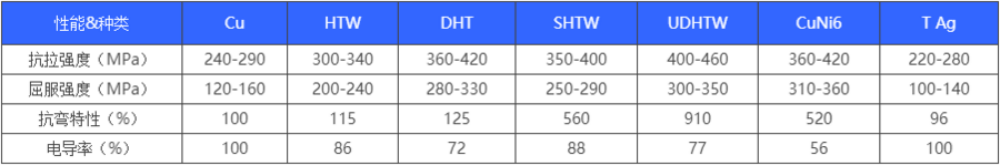

2.1 Litšobotsi tse phahameng tsa terata (HTW, DHT, SHTW, UDHTW):

The high tension terata ke koporo alloy self-adhesive terata enamelled e etselitsoeng ka ho khetheha bakeng sa litlhoko tsa kopo ea thepa e phahameng ea mechine. Mehlala ea eona e bitsoa HTW, DHT, SHTW, UDHTW; E sebelisoa lits'ebetsong tse nang le litlhoko tse phahameng tsa khanyetso ea ho koba le ho tšepahala. terata e phahameng ea tsitsipano e na le khanyetso e phahameng ea tsitsipano, ho ts'epahala, conductivity le khanyetso ea ho kobeha ho feta terata ea koporo ea enamelled.

sebopeho:

·Matla a matla a 20-90% a phahame ho feta a terata ea koporo e nang le enamelled, e loketseng ho phalla ka lebelo le phahameng, 'me leoto la solder ha le bonolo ho robeha.

·Boitšoaro>77%.

·Lera la motheo la insulating, lera le itšebetsang le terata ea koporo e nang le enamelled lia tšoana.

·Ts'ebetso ea ho cheselletsa ka kotloloho ho tšoana le ea terata ea koporo e nang le enamelled.

2.2 Litšobotsi tse phahameng tsa terata ea alloy (CuNi6):

The high impedance alloy terata ke copper alloy enamelled terata e khethehileng e etselitsoeng litlhoko tse khethehileng tsa kopo ea impedance, 'me mohlala oa eona o bitsoa CuNi6;

sebopeho:

·Boleng ba ho thibela mithara ka 'ngoe ke makhetlo a 6-8 ho feta oa terata e nang le koporo e entsoeng ka koporo, e loketseng jenereithara kapa khoele e khethehileng e sebelisetsoang ho lokisa boleng ba Q.

·Lera la motheo la insulating, lera le itšebetsang le terata ea koporo e nang le enamelled lia tšoana.

·Ts'ebetso ea ho cheselletsa ka kotloloho ho tšoana le ea terata ea koporo e nang le enamelled.

· Litšobotsi tse ntle tsa phetiso ea lets'oao.

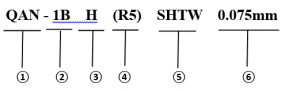

2.3 Tlhaloso ea khoutu ea sehlahisoa:

1. Mofuta oa khoutu ea lera la insulating

AN=UEW e chesehang

ZN=PEW e sa cheseheng

XYN=EIW e sa cheseheng

2. Pente botenya ba filimi (1,2,3, e bua ka IEC le litekanyetso tsa bareki).

3. Kereiti ea ho hanyetsa mocheso oa insulation

F=155

H=Sehlopha sa 180

S * e emetse thini e tlase ya mocheso o tlase

4. Mofuta oa ho iketsa sekhomaretsi lera (R self-sekgomaretsi lera bobeli softening mocheso ≤ 130 ℃, R5 self-sekgomaretsi lera bobeli softening mocheso ≤ 160 ℃, R7 self-sekgomaretsi lera bobeli softening mocheso ≤ 190 ℃, C self-sekgomaretsi lera ke moea o chesang oa joala o sebelisoang habeli, SV e ikgomaretsang lera e thatafatsa mocheso).

5. Sehlopha sa motsoako

HTW=Tsela e tlwaelehileng e nang le tsitsipano e phahameng

DHT=Tsela e thata e phahameng

SHTW=terata e nang le tsitsipano e phahameng haholo

UDHTW=terata e eketsehileng ea tsitsipano e phahameng

6. Bophara ba lebitso la mokhanni (mm).

Sehlopha sa lihlahisoa: Φ 0.030-0.15mm (AWG52-34)

.jpg)

-300x300.jpg)

2-300x300.jpg)

1-300x300.jpg)

1-300x300.jpg)